SELLING OFFER

Seek co-innovation with global enterprises and governmental institutions

3D-printed zirconia ceramic-based implants

286 2022. 5. 25.

Summary

A South Korean company has come up with a nanometer level of the close manufacturing process which can be made in a short time. This company makes 3D shapes with a computer-controlled sequential layering of advanced ceramic materials. The nano and micro-processing technology are used with an additive manufacturing system with ceramic as the base material.

Advantages and Innovations

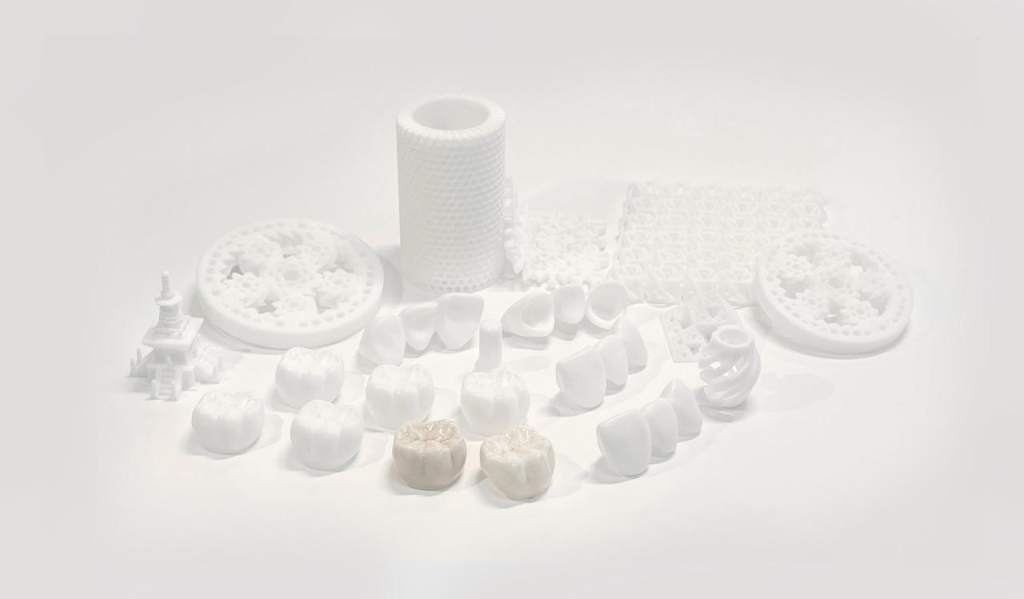

This company’s innovative manufacturing systems for dental implants can produce very precise artificial teeth with highly convoluted surfaces of the tooth and dental prostheses with dimensions of up to 70µm. This precision is essential as for implants, color, strength, and formability are quite crucial. This is superior compared to conventional manufacturing techniques such as subtractive mining or injection molding.

Conventionally titanium is used as an implant but over time the titanium material degrades or causes allergy for the patients. Moreover, the shiny metal shows on the person's mouth as they open their mouth or smile. The zirconia-based material is as lightweight as titanium and durable at the same time. Compared to the titanium implants ceramic implants have a low affinity for the plague; attracting and retaining less plague and a lower adhesion to bacteria. Therefore ceramic-based implants tend to be much cleaner than their other counterparts. Ceramic implants are a more recommended option for individuals who want to achieve the best cosmetic result. With the fast precision technology of this company, 3D printing ceramic zirconia implants have become more reliable, accurate and easy to manufacture.

Stage of Development

Description

Teeth and smiles contribute a lot to make a good image about a person. Pearly white, perfectly aligned teeth bring joy as well as a major source of confidence for people. In order to get the right colour and structure of the teeth that are very personalised to individuals, 3D printed ceramic zirconia implants are being recommended more by dentists.

The digital manufacturing process for dental implants has become a new trend globally because of its instant manufacturing ability and accurate use. The artificial tooth industry is growing fast and this company is providing a one-stop solution for digital dentistry products.

Their patented technology uses nano and micro-processing technology to manufacture particles with physical, chemical, and electrical properties depending upon the desired type of product. With this type of biotechnology, they are providing two types of product support:

- Support and model design techniques for optimizing the output of ceramic products.

- Precision ceramic 3D printing technology that can reliably stack high viscosity ceramic resins.

These dental implant products are chemically neutral, biocompatible, and scratch and corrosion-resistant. While they have such advantages and have high demand, they lack a mass producer worldwide.

The company is collaborating with a leading university in Seoul and other industry experts to bring out the finest outcome. They also have their material certified by the Ministry of Food and Drug Safety in South Korea and are looking for overseas market expansion.

Technology Keywords

Market Application Keywords

Sector Group

Type and Size of Client

Type and Role of Partner Sought

- Type of partner sought:

Industries

- Specific area of activity of the partner:

Dental clinics, Industries that require high precision 3D printing. Industries that work with ceramic materials.

Type of Partnership Considered

Manufacturing Agreement

Company

Internal Reference

Category

Express your interest in this opportunity.