SELLING OFFER

Seek co-innovation with global enterprises and governmental institutions

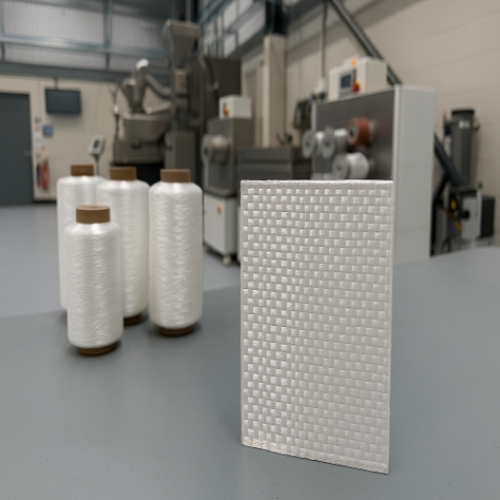

Recyclable Self-Reinforced PET Composites for Lightweight, High-Performance Mobility and Construction

68 2025. 7. 14.

Summary

This technology presents a recyclable, high-performance or thermoplastic composite based on self-reinforced PET (srPET). Unlike conventional fiber-reinforced plastics (FRPs), this technology uses only PET for both the matrix and the reinforcement, it eliminates the need for material separation at end-of-life, enabling true mono-material recycling. Notably, the material is made from 100% recycled feedstock (PCR-PET), aligning with global circular economy and carbon reduction goals. It addresses key challenges including recyclability, regulatory compliance, and lightweighting in mobility industry, while also extending its applicability to the construction materials sector. With excellent mechanical strength, formability, and compatibility with standard thermoplastic processing (e.g., press molding, lamination), the material is suitable for automotive, aerospace, defense, and building industries. Target adopters include OEMs and Tier-1 suppliers looking to replace traditional plastics or metals with sustainable, high-performance alternatives.

Advantages and Innovations

The material is a self-reinforced composite made entirely from PET, delivering superior mechanical performance compared to traditional unfilled thermoplastics. It exhibits high impact resistance, structural rigidity and dimensional stability, low shrinkage, and excellent formability.

It supports standard thermoplastic processing methods, including extrusion, lamination, thermoforming, and hot-press molding. The technology can be extended with functionalities such as flame retardant formulations, sandwich panel structures for construction and mobility sectors, and thermal insulation properties.

Stage of Development

Description

The technology is suitable for a wide range of industries, including Automotive (door trims, underbody shields, NVH components), Aerospace (interior panels and non-structural lightweight parts), Defence (anti-stab panels or impact-resistant panels), Marine (lightweight structural covers and panels), and Construction (interior/exterior wall panels, insulation boards, and sandwich panels).

It is especially suited for sectors requiring recyclability, high strength-to-weight ratio, thermal insulation, and regulatory compliance.

The global lightweight materials market is expected to exceed USD 250 billion by 2030. Demand is rising across EVs, aerospace, and defense sectors, while increasing sustainability regulations such as EU ELV and U.S. EPR are accelerating the adoption of circular materials like srPET composites. In the building sector, demand is also growing for carbon-neutral and sustainable construction materials.

Unlike competing solutions, which rely on PP-based or hybrid fiber systems, this technology leverages 100% recycled PET to deliver superior thermal stability, processing compatibility, and recyclability.

Its mono-material structure enables closed-loop recycling without material separation, supporting ESG and circular economy goals.

Beyond mechanical durability and excellent formability, the material also provides built-in insulation performance, offering a clear advantage cost-sensitive, regulation-driven markets, green construction, and lightweight consumer products.

The ideal business partners include OEMs and component manufacturers seeking sustainable alternatives to traditional plastics, glass-fiber composites, or metals.

Technology Keywords

Market Application Keywords

Sector Group

Type and Size of Client

Type and Role of Partner Sought

OEMs and Tier-1 suppliers in automotive and aerospace, composite and construction material manufacturers, research institutions in green materials seeking high-performance, recyclable alternatives to traditional plastics and composites.

Type of Partnership Considered

License agreement

Research cooperation agreement

Company

Internal Reference

Category

Express your interest in this opportunity.