SELLING OFFER

Seek co-innovation with global enterprises and governmental institutions

High-efficient work-holding technology through magnetism controlling

264 2021. 9. 10.

Summary

A Korean SME, based in Seoul, has developed a new method of the work-holding system which is controlled by magnetism. This technique can be applied to a wide range of industries such as automobiles, machinery, and lift/hold automation. The technology can give solutions to the problems that occur in the existing work-holding system, enhancing energy efficiency. The company is looking for international partnerships under license agreements.

Advantages and Innovations

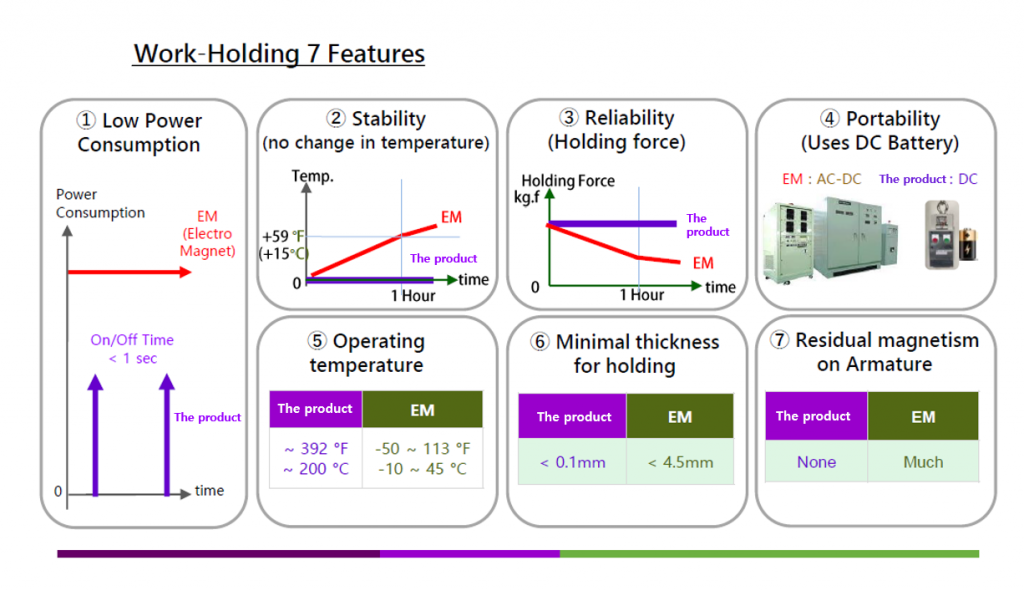

By taking advantage of low power consumption and no additional devices needed for operation, the magnetism controlling technology can be implemented as portable magnetic modules with various structures. As a result, the technology can be applied to a wide range of industries, even where conventional electromagnets are not currently applicable. This system consumes low DC power only at the moment of attaching and detaching. It is a portable and flexible structure with a strong holding force.

Stage of Development

Description

An SME from South Korea, was established in 2010 with a goal of using magnetic energy as another energy source. The company is specialized in developing and licensing original magnetism controlling technology.The firm is wishing to have international partners under license agreements.

Work-holding refers to any device that is used to secure a workpiece against the forces of machining. The most basic work-holding device is a simple clamp, but work-holding can also involve complex fixtures that are custom-built for particular parts.

Current electromagnetic work-holding technologies are effective, but not efficient. The company has identified three aspects of conventional electromagnet work-holding technologies that contribute to this lack of efficiency: 1) A large amount of energy is required for current electromagnets to initiate and terminate a hold. 2) Current electromagnets require continuous power consumption in order to remain attached to the item being held. 3) This massive amount of continuous energy consumption puts off a lot of heat, forcing companies that use electromagnets to also invest in cooling technologies to offset this heat.

The company has been able to address each of these issues with their cutting-edge technology. Through extensive R&D and innovation, they have developed a magnetism controlling technology that: 1) Uses very little energy (for less than 1 sec) to initiate and terminate a hold 2) Does not require continuous power consumption, or any additional devices, for operation 3) Has no issues with overheating (due to its very limited power consumption)

Technology Keywords

Market Application Keywords

Sector Group

Type and Size of Client

Type and Role of Partner Sought

The Korean SME is interested in having partnerships with the following types of industries, 1) Automobile 2) Machinery 3) Lift/Hold 4) Factory Automation 5) Aeronautics under license agreements.

Type of Partnership Considered

Company

Internal Reference

Category

If interested, please press this button.

We will answer you soon.