SELLING OFFER

Seek co-innovation with global enterprises and governmental institutions

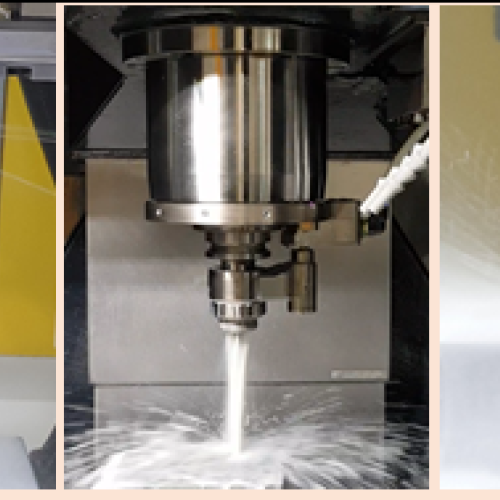

Machine tool direct injection tool holder technology

258 2024. 2. 1.

Summary

The centrifugal force generated by spindle rotation is converted to centripetal force to direct the coolant to the Pressurised direct injection and pressurised oil hole injection from the centre of the toolholder.

The innovation is the world's first machine tool direct injection tool holder technology.

The Company are seeking European partners for jointly research, develop and distribute this technology for the machine tool cutting industry.

Advantages and Innovations

- Innovation

It is a technology that converts centrifugal force into centripetal force and pressurized direct injection in proportion to machine tool spindle rotation power as a pressurized direct injection technology, it has three injection functions required for the cutting process with one system, and can accurately and smoothly inject coolant into the cutting part even in various cutting process situations.

It is a pressurized injection technology that can accurately and smoothly inject coolant into the cutting part even in various cutting process situations.

Coolant pressurized direct injection toolholder that can maximize cutting productivity system that can maximize cutting productivity.

2. Advantages

The C-jet pressurized direct injection toolholder system is a toolholder system that prevents tool chatter and minimizes friction heat generated during the cutting process and facilitates lubrication, thereby improving cutting tool machinability and reducing wear.

This technology is not affected by the centrifugal force generated when the spindle rotates, so it can accurately inject coolant into the machining area.

It is a direct injection toolholder system that can accurately inject coolant into the machining area, and it is a toolholder technology that realizes a clean cutting process by suppressing mist generation. It is mounted on machining centers and turning centers that perform cutting operations. It is applied to cutting processing.

Stage of Development

Description

The spread of centrifugal force generated when the main shaft of the machine tool rotates centripetal force generated when the main shaft of the machine tool rotates.

The centripetal force generated by scattering (spreading) problem caused by center-through coolant injection of conventional center-through coolant injection.

The direct coolant injection system accurately injects coolant to the cutting point regardless of direct coolant injection toolholder system that accurately injects coolant to the w working point regardless of the length of the cutting tool.

- Optimized and advanced the cutting process of machine tools

The cutting quality is improved by maximizing the cooling effect of the processing heat at the cutting point, and the cutting efficiency and cutting chip discharge function are enhanced by strong pressing force.

It solved the problem of chipping in the cutting process by strengthening the cutting chip discharge function.

It also solved the problem of chipping in the cutting process by strengthening the cutting efficiency and cutting chip discharge function.

It is a coolant pressurized direct injection tool holder system.

Technology Keywords

Market Application Keywords

Sector Group

Type and Size of Client

Type and Role of Partner Sought

- Machine tool manufacturer or toolholder system manufacturer

- A manufacturer of machine tools / toolholder systems for machine tools that wants to invest in technology and develop the market.

Type of Partnership Considered

Financial agreement

Company

Internal Reference

Category

Express your interest in this opportunity.